Product Description:

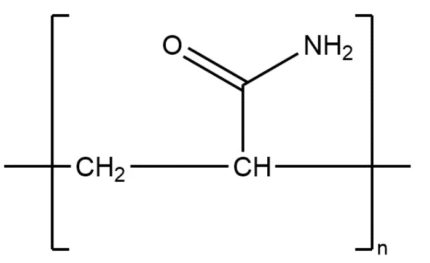

PAO drag reducer: 2–8×10⁶ Da oil-soluble powder that injects 10–30 ppm to suppress eddies, cut friction 30–70 %, stay tough at –40 °C and shear-stable—ideal for boosting throughput or saving energy in crude/product pipelines.

Process Overview:

PAO is manufactured in three continuous, solvent-free steps:

- Feedstock Selection – A C9–C10 cut from Fischer-Tropsch synthesis, rich in linear α-olefins (≥ 95 % 1-decene), is used as the sole monomer source.

- Oligomerization & Saturation – The olefin stream is oligomerized over a proprietary Lewis-acid catalyst, then fully hydrogenated in a fixed-bed reactor (Pd/Al₂O₃, 120 °C, 30 bar) to yield saturated, iso-paraffinic chains with targeted molecular weights.

- Short-Path Distillation – Two-stage wiped-film units remove light ends and heavy waxes, delivering a colorless, > 99 % pure PAO base oil with polydispersity < 1.1.

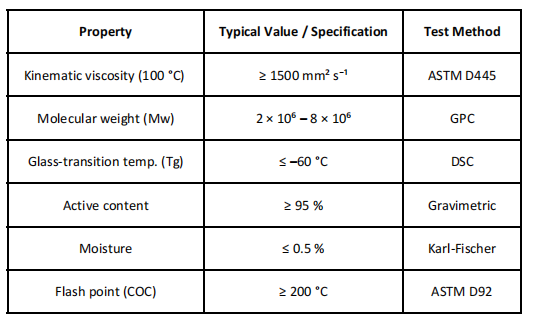

Performance Specifications:

Key Applications:

PAO’s high VI, low pour point and oxidative stability make it the synthetic base stock of choice for:

- Automotive Engine Oils – 0W-16/20 grades; reduces cold-crank viscosity by 40 % and doubles Sequence IIIH oxidation life versus Group III oils.

- Industrial Gear & Bearing Lubricants – Operates from –60 °C to 200 °C without varnish formation (FZG ≥ 12).

- Fuel Additive Carriers – Solubilizes detergents and cetane improvers while cutting injector deposits by 55 % (DW-10 test).

Performance Highlights:

- Viscosity-Temperature Behavior – VI > 140; kinematic viscosity change < 3 % between 40 °C and 100 °C.

- Low-Temperature Fluidity – Pour point ≤ –54 °C; CCS viscosity at –35 °C < 600 mPa·s (5W rating).

- Oxidation Resistance – TAN rise < 1.0 mg KOH g⁻¹ after 504 h TOST (ASTM D943); 4× life of API Group II mineral oil.

Main Features:

- Ultra-high molecular weight & highly branched structure → ≥ 60 % drag reduction at 10–30 ppm typical dosage.

- Excellent low-temperature toughness – suitable for crude/product pipelines down to –40 °C.

- Superior shear stability: > 80 % drag-reduction retention after 24 h continuous pumping.

- Fully compatible with non-polar hydrocarbons – rapid dispersion without additional emulsifiers.

Recommended Applications:

- Onshore / offshore long-distance crude oil pipelines

- Product pipelines (gasoline, diesel, jet fuel) for throughput increase & energy saving

- Chemical feedstock (naphtha, aromatics) logistics cost reduction

Usage Instructions:

- Inject continuously at pump station outlet via metering pump;

- Start at 10 ppm; fine-tune to 15–30 ppm based on field friction monitoring;

- Compatible with common corrosion inhibitors and pour-point depressants; avoid co-injection with strong oxidizers.

Packaging Options:

- 20 kg moisture-proof kraft paper bags

- 500 kg flexible big bags

- Bulk ton-bags or ISO-tank on request